The mold manufacturing industry is constantly evolving. As a result, options for overcoming complex mold texturing challenges are evolving, too.

Our complex marketplace demands new and innovative design possibilities with higher accuracy and tighter tolerances while keeping production times as short as possible. For example, some projects may require depth or detail unachievable by acid etching, while others demand consistent results with high-volume multi-cavity tools.

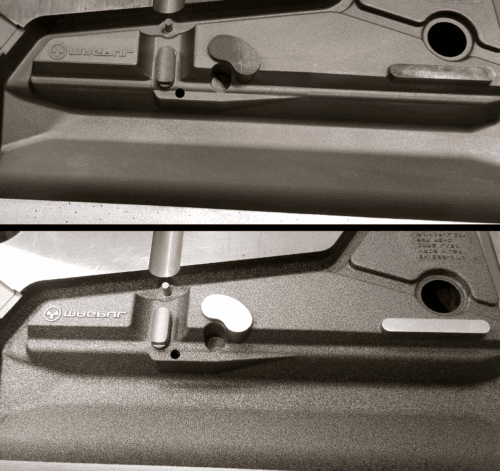

Laser texturing might be the right solution to overcome these complex challenges. Here are a few key advantages to consider.