Modern Mold Texturing: How St. Paul Engraving Sets Industry Standards

As the manufacturing world accelerates toward smarter, more efficient processes, we strive to continue to set the pace in mold texturing innovation. With a commitment to precision, innovation, and unmatched quality, St. Paul Engraving is not just keeping up with industry standards—we’re setting them.

Leading with Laser Precision

At the core of our operation is state-of-the-art laser texturing technology, enabling us to deliver complex, high-resolution surface finishes with exceptional accuracy. From fine-grain textures to deeply contoured surfaces, our laser systems offer repeatable results that eliminate the variability of traditional methods.

By replacing older acid etching techniques with environmentally responsible laser processes, we’re helping our partners achieve greater design freedom, faster lead times, and superior part-to-part consistency—all while meeting the rigorous demands of today’s global manufacturing markets.

Laser S 1200 FS

The Laser S Series 1200 U w/ FS capabilities, redefining precision, efficiency, and quality in the plastic injection molding industry.

Laser S 600

Laser S 600 series, introduced in 2020, delivers exceptional agility, quality, and efficiency, operating 24/7 with a Z focus shifter and dual flexi-pulse sources.

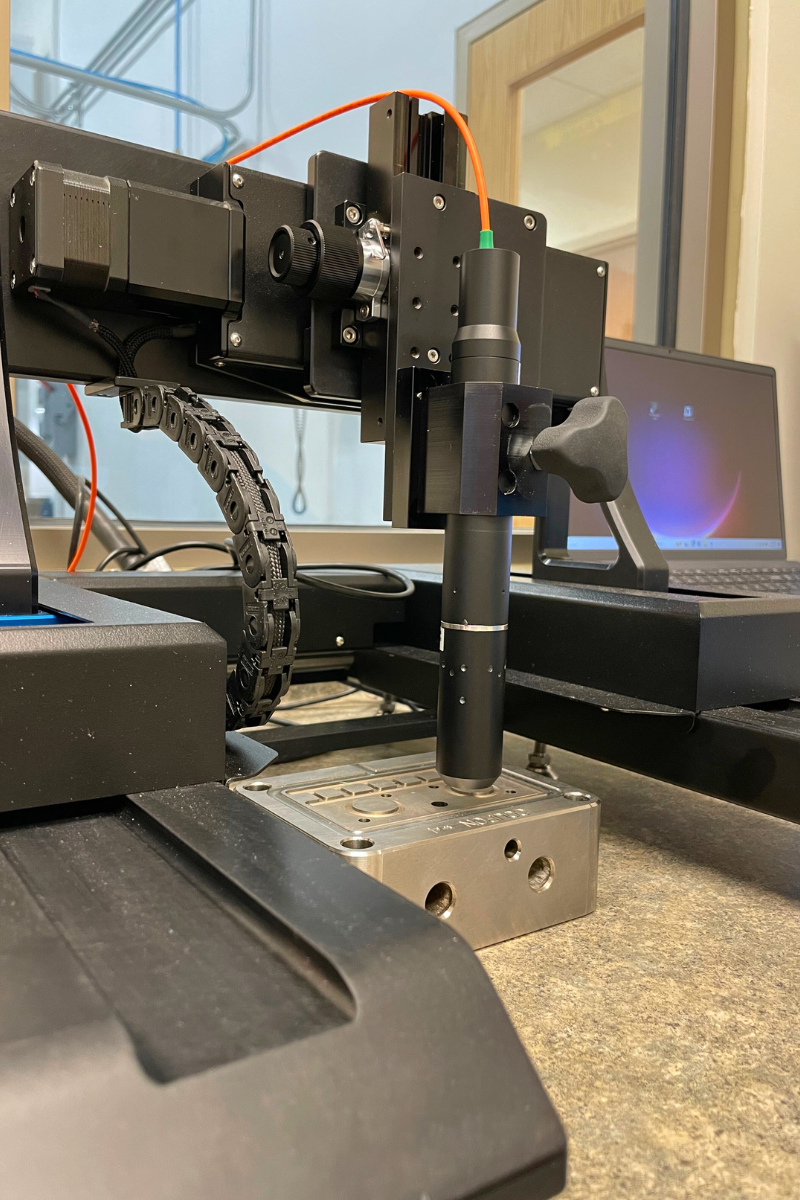

JR100 | Profilometer

The JR100 Profilometer allows us to closely examine surface finishes, ensuring precise and consistent results.

Automation for Efficiency & Scale

Our investment in automation and process integration has elevated our throughput and responsiveness, enabling us to handle everything from single cavity tools to high-volume production projects. Robotic part handling with 3R Automation, CAD-to-laser workflow automation, and real-time monitoring systems allow us to operate with efficiency and accuracy—regardless of project complexity.

This means less downtime, fewer manual steps, and faster delivery, allowing our clients to remain competitive in a rapidly evolving manufacturing environment.

Piece-Part Precision & Customization

Whether it’s a full tool or an individual components, our piece-part capabilities empower us to handle jobs of all shapes and sizes with extreme detail. This flexibility is especially valuable for high volume production, mold repairs, design revisions, or pilot projects that demand the same level of care as a full-scale production run.

Quality Control Without Compromise

Our reputation has been built on precision and trust, supported by a robust in-house quality control protocol. Every project undergoes detailed inspection using advanced profilometer equipment and visual validation processes to ensure conformity to exact client specifications.

We understand the cost of rework—and we’re committed to delivering results right the first time.

Experience It for Yourself

As we continue to pioneer the future of surface texturing & engraving, we’re excited to share what’s next. This spring, we’re preparing to host an exclusive Shop Open House event at our facility in early June. Attendees will experience live demonstrations of our laser texturing capabilities, tour our production floor, and connect with the experts who make it all happen.

The event will conclude with a casual networking hour—featuring food, drinks, and conversation among industry peers.

Stay tuned on our social channels for the official date announcement—and don’t miss the opportunity to see how SPE is shaping the future of surface texturing.